Bond self-adhesive decorative panels

Our self-adhesive design panels, marked with the abbreviation “SA”, are equipped with a strong adhesive layer on the back of the decorative panel – made of high-quality acrylates or synthetic rubber – and can therefore be attached quickly and easily to non-absorbent surfaces. The self-adhesive design panels are glued directly to the substrate without additional glue, allowing for an expansion joint.

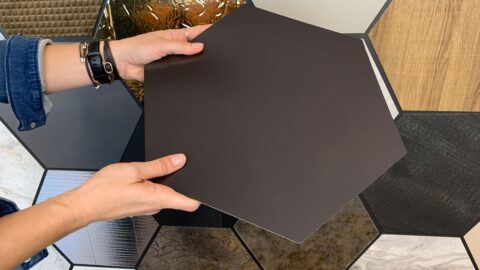

Back of a self-adhesive decorative panel

Suitable substrates for self-adhesive decorative panels

The self-adhesive panels are suitable for non-absorbent surfaces such as coated MDF/chipboard, glass, metal, plastic, etc.

Tip: Identify non-absorbent surfaces

You can recognize non-absorbent substrates by dripping a drop of water onto the surface – if this does not sink in but remains on the surface, it is a non-absorbent substrate.

The self-adhesive equipment is not suitable for ceiling applications. Alternative processing options are available upon request.

Left: absorbent substrates & right: non-absorbent substrates

Prepare the substrate:

The substrate must be dry, smooth, free of loose parts, dust, dirt, grease, wax and silicone. Never mount SIBU DESIGN panels on uneven surfaces, as this may result in a loss of visual quality.

To achieve maximum adhesion, non-absorbent surfaces must always be cleaned with alcohol (ethanol, isopropyl alcohol).

Retain an expansion joint:

When bonding self-adhesive design panels (SA), an expansion gap of approx. 2 – 3 mm must always be maintained at the panel edges!

If the ambient temperature is high or the temperature fluctuates sharply, the expansion joint should be enlarged or a smaller panel format should be selected.

Back of a self-adhesive decorative panel

Glue edges exactly

Apply self-adhesive decorative panel

Remove protective foil

Assembly

- In the case of self-adhesive design panels (SA), remove the adhesive cover step by step, avoiding contact with the adhesive surface and press as firmly as possible onto the subsurface.

- Absolutely avoid the formation of bubbles (air pockets).

- For large areas, it is best to use a medium-hard rubber hand roller with a width of approx. 170 mm.

The final adhesion is reached after 24 hours at room temperature.

Good to know:

Avoid the formation of bubbles

The formation of bubbles and air pockets must be avoided at all costs. Use a medium-hard rubber hand roller!

Retain an expansion joint!

In general, an expansion joint of approx. 2-3 mm must be maintained at the board edges.

Storage

Self-adhesive design panels should be processed within 12 months.

Adhesive force

The final adhesion is reached after 24 hours at room temperature.

Other interesting articles:

Features of the rear of the decorative panel

Non-adhesive (NA), self-adhesive (SA) or magnetic. We offer the right version for every area of application to optimally support your implementation.

Magnetic Equipment & Metal Foil

In this article you will learn everything about the magnetic equipment of the decorative panel, suitable substrates as well as installation.