PVA pre-treatment

So that design panels are suitable for PVA pressing (bonding with white glue), depending on the material, they must either be pre-treated on the back side through an additional production process at SIBU DESIGN or manually sanded, i.e. roughened.

Important notes on pretreatment

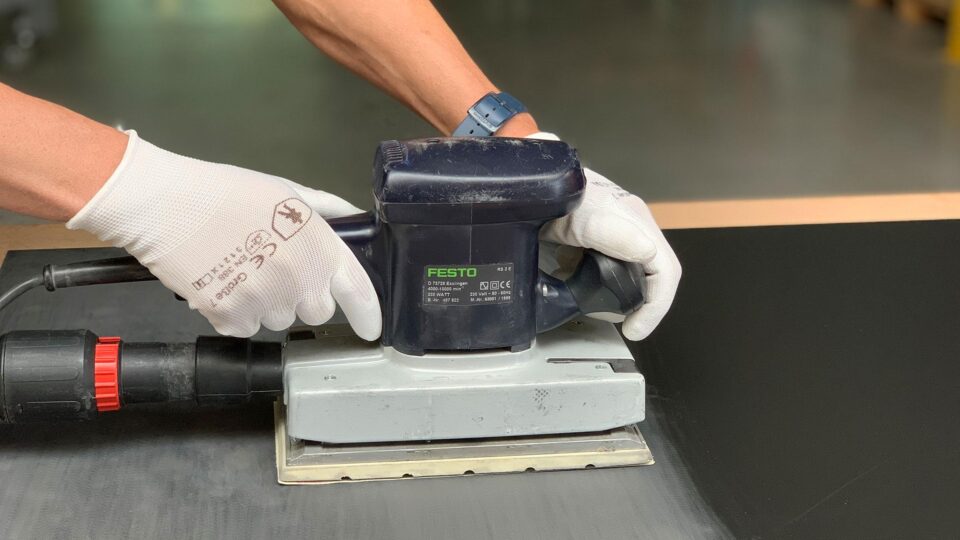

Orbital sander / random orbital sander

To achieve the desired surface tension of the back of the decor panel, you can use orbital sanders or random orbital sanders.

Sandpaper

We recommend sandpaper with a 80 grains.

Surface Tension & Test Ink

The surface tension of the back of the decor panel must be at least 46 mN/m. A special test ink can be used to check whether the desired surface tension is achieved.

When is manual pretreatment necessary?

Depending on the product:

In the technical spreadsheet of each product you will find if a pre-treatment is necessary at all, as well as the information if SIBU DESIGN offers the decorative panel already pre-treated. If you order the product already pre-treated, you will see the abbreviation “PVA” in the product name, which highlights that the sheet has been pre-treated.

Time-dependent:

A decorative panel pre-treated by SIBU DESIGN must be pressed within 2 months, otherwise the industrial treatment (not visible to the naked eye) will decrease and must then be roughened again manually with a sander.

Roughening the back of the decor panel

Test ink for checking the surface tension

Test ink shows that the surface tension is not sufficient. (line blurred)

Test ink shows that the surface tension is OK. (line remains)